We’re thrilled to announce the speakers and full program for KA Connect 2025, taking place August 12–15 at the incredible Sundance Mountain Resort in Utah.

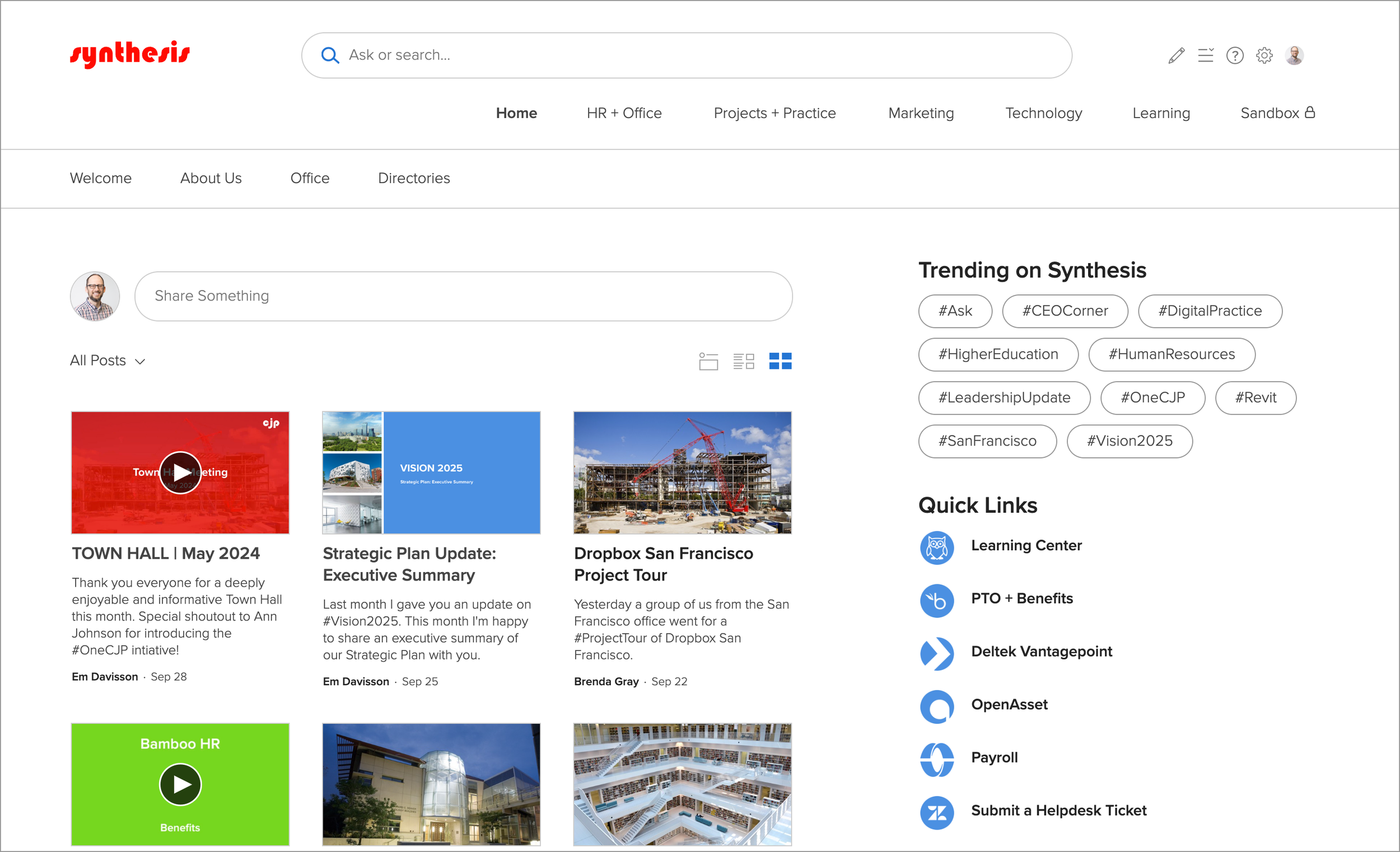

Read moreINTRANET TOUR | Launching Synthesis @ Snøhetta

Featured Guests

Kate Grimes, Director of Knowledge

Webinar Summary

We are pleased to share this inside look at the Guide, Snøhetta’s Synthesis intranet. Our tour guide is Kate Grimes, Director at Snøhetta.

Read moreAI SEARCH FORUM | Unlocking the Power of Synthesis AI Search

Featured Guests

Jim Martin, Vice President, CIO, Shepley Bulfinch

Jess Purcell, Design Technology Manager, Shepley Bulfinch

Kathy Schumann, Employee Experience and Communications Director, Mead & Hunt

Andy Knauf, Chief Information Officer, Mead & Hunt

Gillian Hutchison, Global Project Operations Director, RIOS

Webinar Summary

We’re excited to bring together three leading AEC firms—Shepley Bulfinch, Mead & Hunt, and RIOS—for a deep dive into how they are leveraging Synthesis AI Search to transform knowledge discovery, streamline workflows, and drive firm-wide adoption.

Read moreA Single Search Box for Firmwide Knowledge

What if you could have a conversation with your firm’s knowledge?

Synthesis AI Search gives AEC firms a single search box for firmwide knowledge—helping you instantly find the answers you need across intranet content, project data, and industry software like Deltek, Unanet, aec360, OpenAsset, Newforma, and Zendesk.

Less time searching. More time doing the work you love.

In this video overview, we'll show you how Synthesis AI Search helps:

→ Design Technology Teams find expert guidance on BIM, Revit, and more.

→ Marketing Teams instantly pull vetted employees and project data for proposals and communications.

→ Practice Leaders surface best practices on sustainability, materials, and firm standards.

→ HR Teams provide quick, clear answers to employee questions.

It’s like having a research assistant embedded in your firm—so your team can spend less time searching and more time designing, building, and growing.

Introducing Page Sections + Anchor Links

We’re excited to announce the upcoming release of Page Sections + Anchor Links for Synthesis.

This new feature allows users to:

Search for Page Sections – Search now surfaces specific page sections in suggestions and results, allowing users to navigate directly to the relevant content.

Automatic Scroll & Expand – Clicking on a page section from search scrolls you to the correct page section and expands collapsible content when necessary.

Anchor Links – Each section has a unique, shareable link that can be copied and used in emails, Teams, Slack, or Synthesis posts.

New Linking Options – Users can link directly to specific page sections from text links in posts and pages, the content outliner, image blocks, navigation blocks, and Best Bets.

We’ll release this update after the close of business on Friday, February 14th to all Knowledge Architecture clients.

Enjoy!

AI SEARCH DEEP DIVE | Preparing EUA for Synthesis AI Search

Featured Guests

Andrea Moede, Knowledge Specialist

Webinar Summary

We are pleased to share how Andrea Moede, Knowledge Specialist at Eppstein Uhen Architects (EUA), is transforming Connect, EUA’s Synthesis intranet, to fully harness the power of AI Search in order to reduce the amount of time employees spend searching for information, improve productivity, and elevate employee engagement.

Read moreIntroducing Synthesis AI Search Filters

We’re excited to announce the upcoming release of Synthesis AI Search Filters.

This new feature allows users to curate the sources used to generate AI search summaries and top results.

Users can filter by various criteria, such as a specific community, guide, library, content type, and last updated, which helps to narrow down the search results and improve the relevance of the information retrieved.

We will release this update after the close of business on Friday, January 24th to all Knowledge Architecture clients currently in the Synthesis AI Search public beta.

Enjoy!

Synthesis AI Search Is Now in Public Beta

Synthesis AI Search, built specifically for AEC firms, combines next generation search technology with AI to instantly generate rich answers to natural language searches and questions by summarizing the most relevant content on your Synthesis intranet.

Read moreSearching Videos with Synthesis AI

For years, our AEC clients have uploaded a wide variety of videos to Synthesis — town halls, software training sessions, design education materials, and more.

Earlier this year, we upgraded our video technology to include automatic transcriptions, enabling captions and fully searchable transcripts for all videos uploaded to Synthesis. This enhancement addressed two critical needs: accessibility and search.

By combining advanced AI capabilities with video content, we’re empowering firms to unlock the valuable knowledge hidden within their video libraries.

In this short video, we demonstrate how Synthesis AI Search goes beyond traditional search by synthesizing summaries that span all intranet content, including videos.

Each summary includes citations, and when the source is a video, hovering over the citation reveals the video, the precise timestamp of the quoted passage, and even takes you directly to that moment in the video when clicked.

This seamless integration of AI, search, and video offers a revolutionary new way to access and use video content.

If you like to learn more about how Synthesis AI Search can help your firm make the best use of your knowledge, you can schedule a demo or email us at info@knowledge-architecture.com.

PODCAST | The Future of Knowledge Management in AEC Firms

Our Founder + CEO, Christopher Parsons, recently sat down with Evelyn Lee on the Practice Disrupted podcast to talk about the future of knowledge management in AEC firms.

There’s so much happening in the industry right now — large talent shortages, shorter project schedules, and accelerating baby boomer retirements — to name a few, and of course, the emergence of AI as a disruptive and potentially transformative force.

Christopher has been working on knowledge management in our industry for over 20 years, including at two architecture practices, and has come to believe over the last year and a half that AI has the potential to unlock an incredible amount of value for knowledge-based practices by accelerating learning, reducing the time spent searching for and recreating information, streamlining workflows, and empowering your experts to more effectively share their knowledge through the strategic use of AI.

We’re grateful to Evelyn for the opportunity to talk through all of this (and more) and hope you enjoy the episode.

Episode Overview

What is Knowledge Management in AEC Firms? (03:00)

A firm's most valuable asset is its knowledge. Knowledge is “currency” and managing knowledge should be a strategic priority.

Knowledge Management 3.0 (08:00)

Breaking down KM into three eras — documenting explicit knowledge, sharing knowledge via internal social networking, and now, AI-enhanced KM. KM has evolved in response to technological shifts. KM practices have matured and this AI era marks a game-changing opportunity.

Overcoming Cultural Hurdles to Implement AI (11:00)

Lack of transparency and resistance to change can impede AI’s potential in KM. Achieving success with AI isn’t only about the technology, but also about cultivating a firm culture that values curiosity and continuous improvement.

KM for Talent Development and Knowledge Retention (23:00)

KM combined with AI could bridge generational knowledge gaps created by the impending “retirement cliff” in AEC. Firms can help equip younger generations by sharing the insights of seasoned professionals, effectively accelerating the development of talent in an industry where expertise takes years to cultivate.

Transferring Critical Soft Skills (29:00)

The importance of using storytelling to capture and transfer the soft skills and judgment of experienced professionals. Project-based storytelling can unlock the “invisible” expertise of seasoned practitioners — insights that go beyond technical knowledge to capture valuable decision-making and communication skills.

Future of Knowledge Management with AI (36:00)

AI can “unlock” the value of an organization’s knowledge by making it searchable and accessible in real-time. It can search through years of internal documents and videos, answer questions, and even direct users to relevant parts of resources.

Adapting to Rapid Change (44:00)

The pace of change in AEC is accelerating and continuous learning is the only sustainable competitive advantage. The need for firms to stay steady and adaptable as they constantly upgrade their knowledge is like surfing a wave, especially in an industry under pressure to evolve.

INTRANET TOUR | Boulder on AI-Driven Knowledge Management

Featured Guests

Todd Henderson, Director of Practice Improvement

Webinar Summary

We are pleased to share this deep dive into how Boulder Associates is leveraging AI to transform their Knowledge Management practices, featuring Todd Henderson, Director of Practice Improvement.

Read moreKA Connect 2025 | Unlocking the Promise of Knowledge Management with AI

KA Connect 2025, our annual knowledge management conference for the AEC industry, will take place at the Sundance Mountain Resort in Sundance, Utah from August 12th to August 15th, 2025.

Our focus will be on Unlocking the Promise of Knowledge Management with AI. We’re excited about this new era of AI-powered Knowledge Management and look forward to discussing how your firm can accelerate learning, reduce the time spent searching for and recreating information, streamline workflows, and empower your experts to more effectively share their knowledge through the strategic use of AI.

We’ll begin each morning together in a general session. In the afternoons we’ll transition to a choose your own adventure format with roundtables, hangouts, an intranet cafe, nature activities, and plenty of unstructured time to connect, reflect, and recharge.

Sundance’s location at 6,100 feet in the north fork of Provo Canyon will provide an inspiring backdrop for you to learn from and with your fellow KA Community members.

Early Registration is Now Open

We’ll announce the full conference program in the spring of 2025. In the meantime, take advantage of early registration pricing while we plan!

INTRANET TOUR | A Quick Look at Synthesis @ BRS

Featured Guests

Eric Stein, Communications Manager

Cheyenne Morin, Marketing Project Manager

Summary

We are pleased to share this intranet tour, in which Eric Stein and Cheyenne Morin share highlights from their BRS Synthesis intranet, Boris.

Read moreSynthesis AI Search for Sustainability Content

In this video, we showcase how Synthesis AI Search transforms how AEC firms find and engage with Sustainability content. You’ll see real-time examples of how our AI synthesizes information from across your intranet, including pages, posts, and even videos, to provide comprehensive, composite answers that traditional search can’t match.

Synthesis AI Search went into private beta in October and will go into public beta in December.

If you like to learn more about how Synthesis AI Search can help your firm make the best use of your knowledge, you can schedule a demo or email us at info@knowledge-architecture.com.

Synthesis AI Search for HR Content

In this video, we showcase how Synthesis AI Search transforms how AEC firms find and engage with HR content. You’ll see real-time examples of how our AI synthesizes information from across your intranet, including pages, posts, and even videos, to provide comprehensive, composite answers that traditional search can’t match.

Synthesis AI Search went into private beta this week and will go into public beta in December.

If you like to learn more about how Synthesis AI Search can help your firm make the best use of your knowledge, you can schedule a demo or email us at info@knowledge-architecture.com.

SNEAK PEEK | Synthesis AI Search for Design Technology Content

We’ll be providing live demos of our new AI Search at Autodesk University (AU) 2024 next week. We thought it would be nice to share a sneak peek at what we’ll be sharing at AU.

AI Search will go into private beta this month and into public beta in December.

If you like to learn more about how Synthesis AI Search can help your firm make the best use of your knowledge, you can schedule a demo or email us at info@knowledge-architecture.com.

NEW FEATURES: Dark Mode, Accessibility Checker, and Full Width Search Bar

We’re pleased to announce the upcoming release of Synthesis Dark Mode, Accessibility Checker, and Full Width Search Bar.

We will deploy this update after the close of business on Friday, October 18th.

Read on to learn more!

Introducing Synthesis Dark Mode + Accessibility Checker

This onboarding video and help center article will provide you with the information you need to configure Synthesis Dark Mode, use our new Accessibility Checker, and make your intranet more accessible and inclusive to your users.

Dark Mode will be disabled for end users initially so that Global Administrators and users with Branding access will have a chance to configure logos, styles, placeholders, and custom CSS to match your company’s brand in Dark Mode. Once configuration for Dark Mode is complete, Dark Mode can be enabled for all users.

We strongly recommend taking the steps outlined in this video before enabling Dark Mode for all of your users.

Learn more about our accessibility roadmap on our website.

Full Width Search Bar? Yes, please.

Our new Full Width Search Bar brings us step closer to the Next Generation Search public beta in December.

Enjoy!

What’s on the Synthesis Roadmap?

Learn more about new Synthesis features in development, in design, and planned for the future, as well as submit product ideas on our interactive product roadmap.

KA Connect 2024 Videos Now Available!

We’re excited to announce that all of the videos from KA Connect 2024 are now available.

Enjoy!

Investing in Synthesis AI, LMS, and Expanded Integrations

I shared my vision at KA Connect 2024 for how the AI revolution, in tandem with our old friend Knowledge Management, are going to impact the AEC industry. I'm excited to share this vision with you and discuss how Knowledge Architecture is preparing for this transformative era by investing in the future of Synthesis, our next generation intranet platform for AEC firms.

The Promise of AI and Knowledge Management

While AI is evolving and promising, it's not perfect on its own. The real magic happens when we combine AI with robust Knowledge Management practices. This combination is set to revolutionize our industry, and here's why:

High-quality, firm-wide knowledge is crucial for AI success

KM practices will unlock AI's true potential in AEC

We're at the beginning of a transformative era for our industry

Our Investments in the Future

At Knowledge Architecture, we're actively working on integrating AI into Synthesis, as well as providing new functionality and expanded integrations to bring more high-quality firmwide content into Synthesis.

Here are some of our key investments:

AEC-Specific Video Transcription: We released an AEC-specific video transcription model to convert videos into searchable text earlier this year. Now the high-quality content contained in videos is accessible to AI and is improving accessibility.

AI Search: Our next-generation search will create new AI-powered search summaries that will answer questions by synthesizing the most relevant information from videos, posts, documents, and web pages across your firm's knowledge base, as well as provide citations for easy validation and deeper dives. AI Search will go into public beta in December of this year.

Expanded Integrations: Over the last year we’ve connected Synthesis with additional leading AEC platforms like Unanet, aec360, Microsoft Dynamics, and Zendesk to complement our existing integrations with Deltek, OpenAsset, and Newforma. We're also exploring future integrations with SharePoint, Teams, and Freshworks, as well as releasing a Search Connector API to allow you to push content from other systems into Synthesis and make it all available for AI Search.

Synthesis LMS: Our upcoming Learning Management System will be designed to enhance learning and development within your organization while also contributing a wealth of new, high-quality content to your knowledge ecosystem. This structured platform for continuous learning will feed directly into our AI Search, making all of this new content searchable on your intranet. Synthesis LMS will go into public beta in 2025.

Looking Ahead

The above investments in AI, combined with strong Knowledge Management practices, will fuel what I believe will be a golden era for Knowledge Management. While Knowledge Management has been around formally since 1995, we're now on the cusp of realizing its full potential. Our investments in Synthesis AI, Synthesis LMS, and expanded integrations are all aimed at helping you harness this potential.

As we navigate this new landscape together, I encourage you to consider how these advancements in AI and Knowledge Management might transform your current and future initiatives. How might AI-powered Knowledge Management enhance your firm's capabilities?

I'm excited about this new era and look forward to discussing how we can help your firm prepare for it. Let's explore how Synthesis can position your organization at the forefront of this AI + KM revolution.

Continue the Conversation

Want to learn how Synthesis can help your firm make the best use of its knowledge?

PODCAST | How Knowledge Management Drives Firm Excellence via Practice Disrupted

Corey Squire, long-time friend of Knowledge Architecture and Director of Sustainability at Bora Architecture + Interiors, appeared on the Practice Disrupted podcast last week to explore his approach to using knowledge management to elevate a firm’s performance and sustainability standards within the built environment.

It’s a super interesting take on how to use knowledge management to both unlock the promise of sustainable design and free up subject matter experts to shape your firm’s vision and culture.

And if you like this episode, we highly suggesting watching Corey’s Intranet Tour of Chaco, Bora’s Synthesis intranet. It’s amazing!

And if you still want more, check out Corey’s KA Connect 2024 talk Knowledge Management: The Secret to Unlocking Sustainable Design.